As an environment-friendly and efficient combustion equipment, low-nitrogen burner has been widely used in industry and commerce in recent years. By reducing the emission of nitrogen oxides (NOx) and improving the efficiency of energy utilization, low-nitrogen burners have become an important development direction of modern combustion technology. This paper will elaborate the advantages of low-nitrogen burner in improving energy efficiency, so as to help related industries better understand and apply this technology and achieve the dual goals of environmental protection and energy saving.

Advantages of low nitrogen burner in improving energy efficiency

- Optimize the combustion process

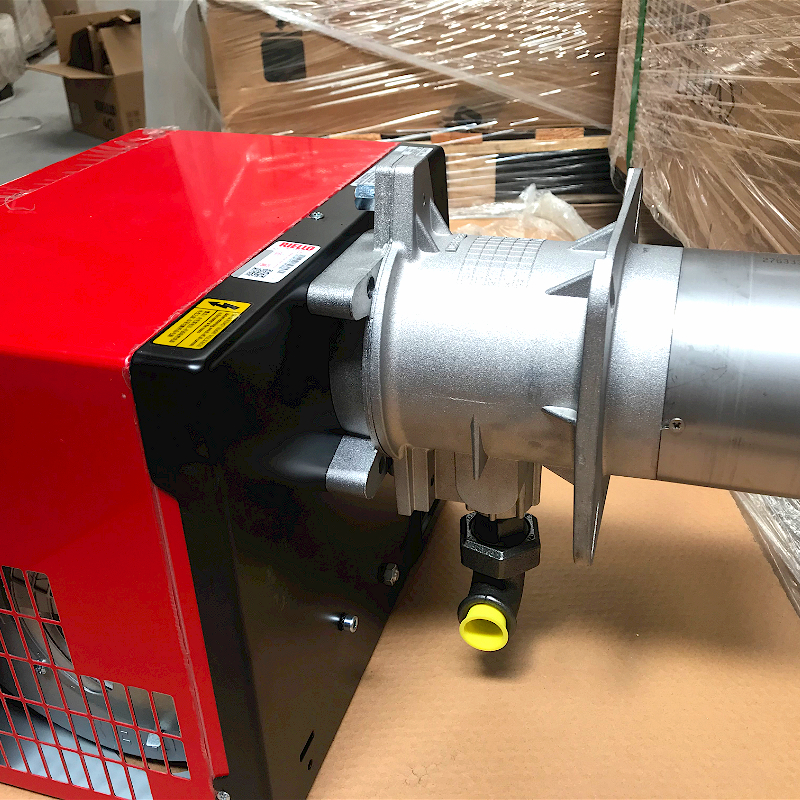

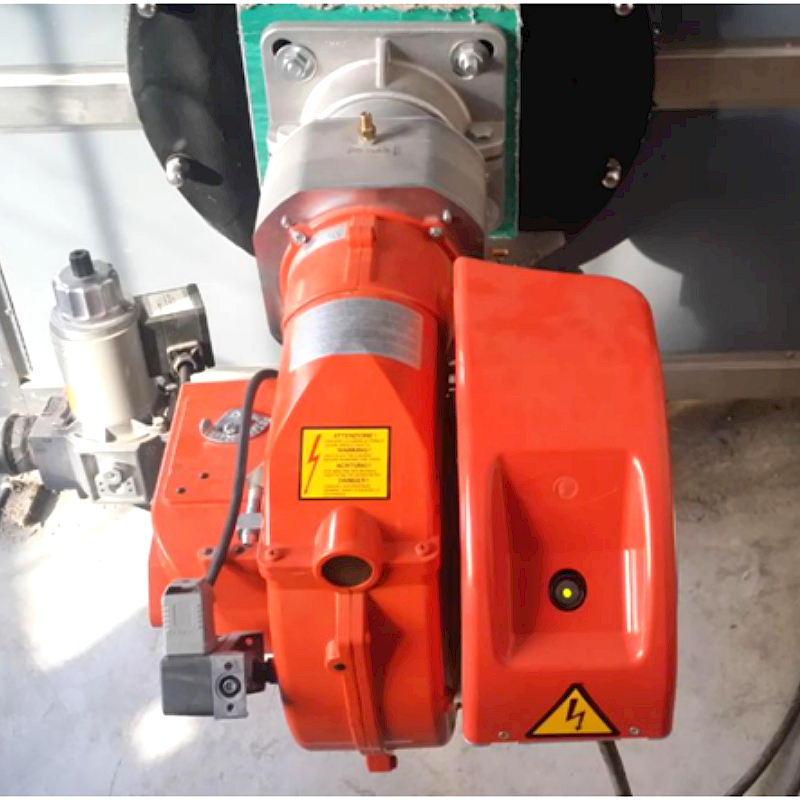

The low-nitrogen burner can make the fuel burn more fully by accurately controlling the ratio of air to fuel in the combustion process. The optimized combustion process not only reduces the loss of incomplete combustion, but also improves the combustion efficiency and reduces the fuel consumption.

- Reduce emissions and improve thermal efficiency.

Traditional combustion equipment is easy to produce a large number of nitrogen oxides at high temperature, while the low-nitrogen burner effectively reduces the generation of NOx by controlling the combustion temperature. While reducing emissions, the optimized combustion temperature can also improve heat conduction efficiency and reduce heat loss, thus improving the overall thermal efficiency.

- Reduce cooling demand

The temperature of flue gas produced by low-nitrogen burner is low, which reduces the demand for cooling system. This not only reduces the cooling cost, but also reduces the energy loss in the cooling process, which is helpful to improve the overall energy utilization rate.

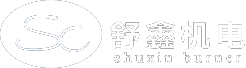

Low nitrogen burner

4, improve the service life of equipment

Because the low-nitrogen burner can burn efficiently at a lower temperature, the damage to the equipment caused by high temperature is reduced and the service life of the equipment is prolonged. The long service life of equipment not only reduces the replacement frequency, but also reduces the maintenance cost and improves the economic benefit of energy utilization.

- Flexible adaptation to different fuels

The low-nitrogen burner can adapt to a variety of fuels, including natural gas, coal, oil and so on. Its efficient combustion control technology enables it to maintain high combustion efficiency and low emission characteristics when using different fuels. The adaptability of this fuel enhances its wide application in different industrial fields.

6, energy conservation and emission reduction policy support

Many countries and regions encourage and support the application of low-nitrogen combustion technology in order to achieve the goal of energy saving and emission reduction. Through policy guidance and economic incentives, enterprises can enjoy tax incentives, subsidies and other policy dividends by adopting low-nitrogen burners, which further improves energy utilization efficiency and economic benefits.

Low-nitrogen burner has obvious advantages in improving energy efficiency, including optimizing combustion process, reducing emissions, improving thermal efficiency, reducing cooling demand, prolonging service life of equipment, flexibly adapting to different fuels and supporting policies for energy conservation and emission reduction. By applying low-nitrogen combustion technology, related industries can not only achieve environmental protection goals, but also significantly improve energy efficiency, reduce production and operation costs and enhance market competitiveness.