In modern industrial production, industrial combustion system plays a vital role. It is not only related to the production efficiency of enterprises, but also directly affects energy consumption and environmental protection. In order to achieve sustainable development and maximize economic benefits, enterprises need to make a detailed cost-benefit analysis of industrial combustion systems. This paper will discuss how to scientifically analyze the cost-benefit of industrial combustion system to help enterprises take advantage in the fierce competition market.

Cost-benefit analysis of industrial combustion system

1, the initial investment cost analysis

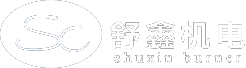

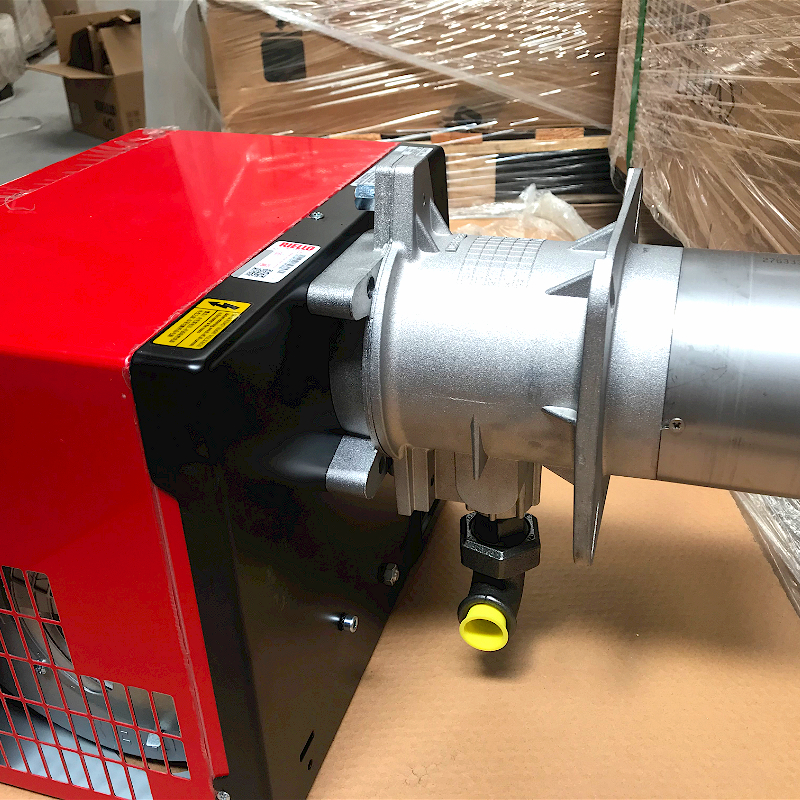

The initial investment of industrial combustion system includes equipment procurement, installation and debugging. This part of the cost directly affects the capital expenditure of enterprises, and requires detailed budget and planning. By comparing the quotations of different suppliers and selecting equipment with high cost performance, the initial investment cost can be effectively controlled.

2, running cost analysis

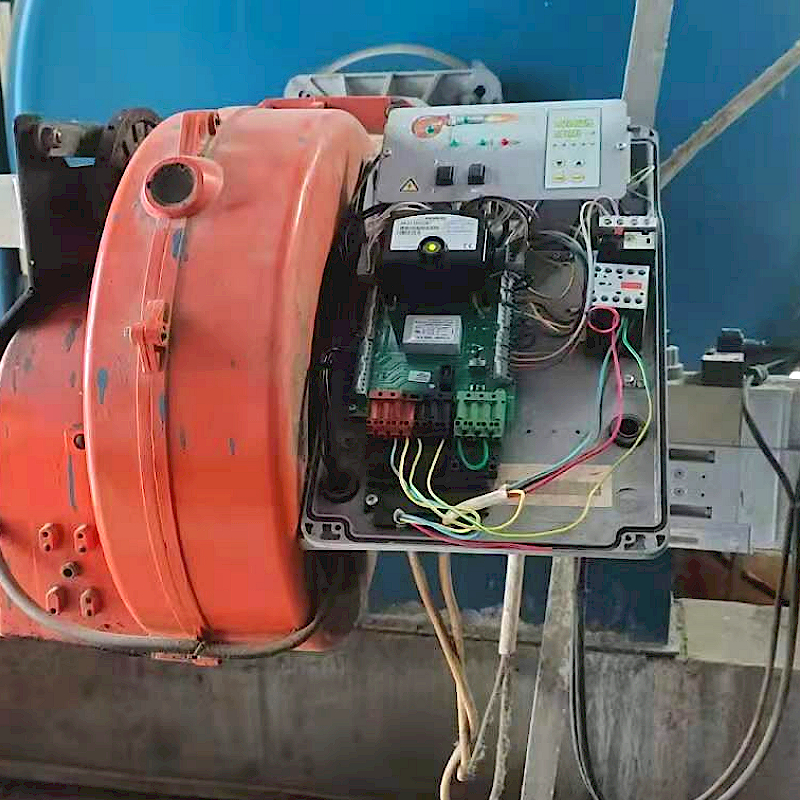

The operating cost of industrial combustion system mainly includes fuel cost, power consumption, maintenance and so on. By optimizing combustion efficiency and selecting high-efficiency equipment, the operating cost can be significantly reduced. For example, using advanced combustion technology and automatic control system can reduce fuel waste and equipment loss, thus saving operating costs.

Industrial combustion system

3, maintenance cost analysis

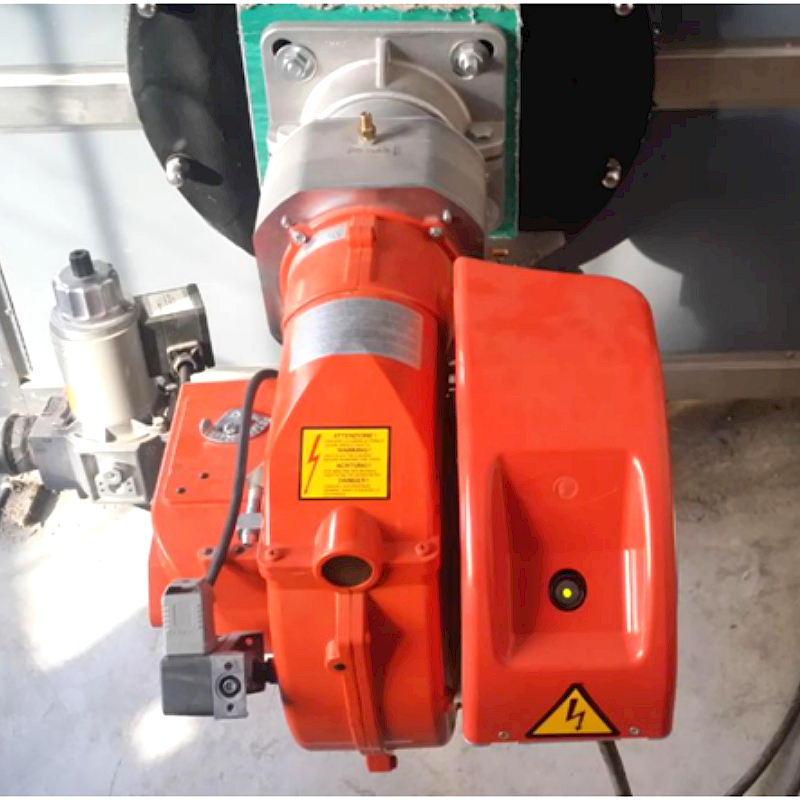

Maintenance cost is an important expenditure in the life cycle of industrial combustion system. Regular maintenance and timely overhaul can prolong the service life of equipment and reduce the failure rate. However, frequent maintenance and replacement of parts will also increase costs. Therefore, under the premise of ensuring the stable operation of the system, enterprises should arrange the maintenance plan reasonably to achieve better cost-effectiveness.

- Environmental cost analysis

Environmental protection is an important part of corporate social responsibility, and it is also a link that cannot be ignored in cost-benefit analysis. Emissions from industrial combustion systems will have an impact on the environment, which may lead to environmental penalties and additional investment in environmental protection facilities. Therefore, choosing a low-emission and high-efficiency combustion system not only meets the requirements of environmental protection, but also reduces the cost of environmental control.

- Benefit evaluation

By evaluating the production efficiency and product quality improvement of industrial combustion system, the economic value of the system can be comprehensively measured. Efficient combustion system can not only improve production efficiency, but also enhance the market competitiveness of products, thus bringing higher economic returns.

In a word, the cost-benefit analysis of industrial combustion system is an important means for enterprises to realize refined management and enhance economic benefits. Through comprehensive cost analysis and scientific benefit evaluation, enterprises can optimize the operation strategy of combustion system and realize the win-win goal of cost control and benefit maximization. In the future development, with the continuous progress of technology, the cost-benefit analysis of industrial combustion system will be more accurate and efficient, which will provide strong support for the sustainable development of enterprises.