Ignition failure in a low nitrogen burner can occur for various reasons, and it is important to identify the root cause to implement the appropriate treatment measures. Below are the common reasons and treatment measures for ignition failure in low nitrogen burners:

- Insufficient Air Supply

1.Reason: Inadequate airflow can prevent the burner from getting enough oxygen to ignite the fuel. This is particularly important in low nitrogen burners that rely on precise air-fuel ratios to reduce NOx emissions.

2.Treatment Measures:

3.Check and clean the air filters, fans, and dampers to ensure proper airflow.

4.Inspect the air blower for adequate performance and replace if necessary.

5.Ensure that the burner’s air-to-fuel ratio is correctly set.

- Low Fuel Pressure

6.Reason: If the fuel pressure is too low, the burner may not receive enough fuel for ignition. This can result in ignition failure or poor combustion.

7.Treatment Measures:

8.Verify the fuel pressure is within the manufacturer’s recommended range.

9.Inspect the fuel supply line for any blockages or leaks.

10.Clean or replace the fuel pump if it is malfunctioning.

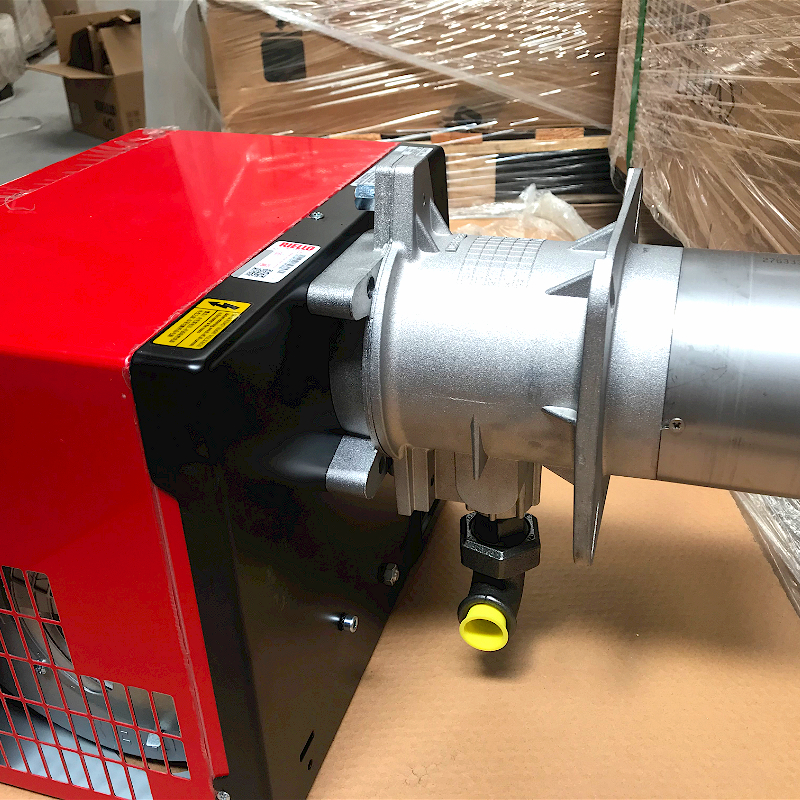

- Faulty Ignition Transformer or Electrode

11.Reason: A malfunctioning ignition transformer or electrode can result in insufficient spark to ignite the fuel.

12.Treatment Measures:

13.Inspect and test the ignition transformer for proper functionality.

14.Check the ignition electrodes for wear, corrosion, or misalignment and replace them if needed.

15.Ensure that the gap between the electrodes is properly set according to manufacturer specifications.

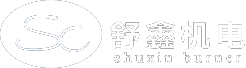

- Dirty or Blocked Burner Nozzle

16.Reason: A clogged or dirty burner nozzle can reduce fuel flow, making ignition difficult.

17.Treatment Measures:

18.Clean the burner nozzle regularly to remove soot, dust, or other debris.

19.Replace the nozzle if cleaning does not resolve the issue.

- Incorrect Fuel Type

20.Reason: If the fuel type being used is not suitable for the burner, or if there are fuel impurities, the combustion process can fail to ignite.

21.Treatment Measures:

22.Verify that the correct fuel is being used, and it meets the required specifications.

23.Use fuel additives if necessary to enhance ignition and combustion properties.

24.Ensure that fuel quality is consistent and free of impurities.

- Defective Flame Sensor

25.Reason: A malfunctioning flame sensor can prevent the burner from detecting a flame, which could stop the ignition process.

26.Treatment Measures:

27.Check the flame sensor for fouling or damage, and clean or replace it if necessary.

28.Ensure the sensor is properly aligned with the flame.

29.Test the sensor to ensure it is functioning properly.

- Improper Burner Settings

30.Reason: Incorrect burner settings, such as air-fuel ratio, burner angle, or combustion chamber configuration, can cause ignition failure.

31.Treatment Measures:

32.Verify that all burner settings conform to the manufacturer’s specifications.

33.Adjust the air-fuel ratio to optimize combustion.

34.Ensure that the burner is installed and aligned properly within the combustion chamber.

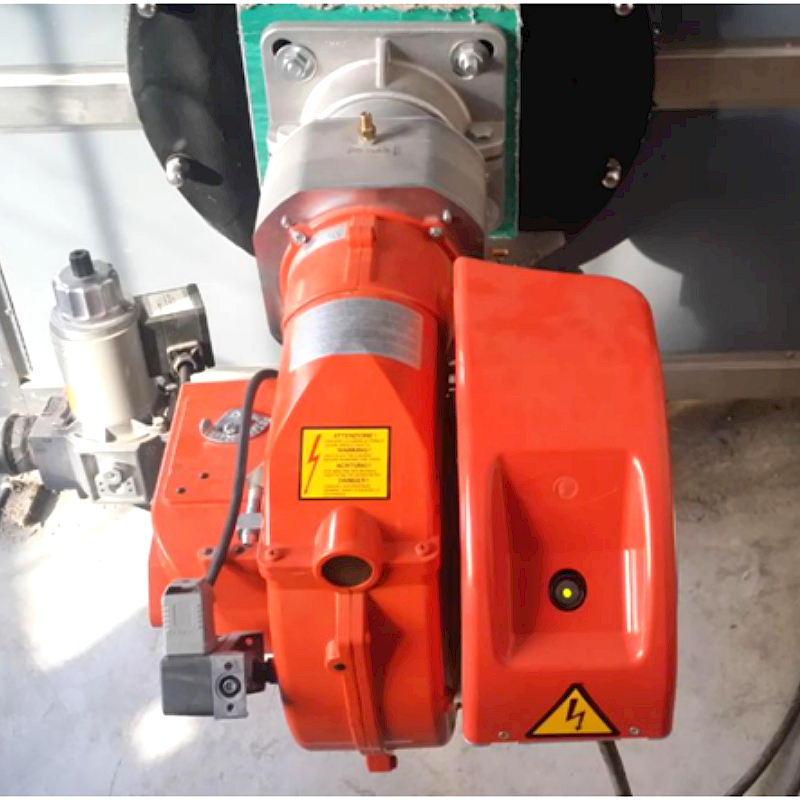

- Electrical Issues

35.Reason: Faulty wiring, electrical connections, or power supply issues can cause ignition components to malfunction.

36.Treatment Measures:

37.Inspect all electrical connections and wiring for damage or wear.

38.Test the burner’s electrical components, such as the control board and wiring, for functionality.

39.Check the power supply to ensure consistent voltage.

- Ambient Conditions

40.Reason: External environmental factors, such as extreme temperatures, humidity, or poor ventilation, can affect burner ignition.

41.Treatment Measures:

42.Ensure that the burner is installed in an environment that complies with the manufacturer’s recommendations for temperature and humidity.

43.Provide adequate ventilation and prevent the burner from operating in confined spaces with insufficient air exchange.

- Improper Start-Up Procedures

44.Reason: Not following the correct start-up sequence can lead to ignition failure.

45.Treatment Measures:

46.Follow the burner’s start-up procedure as outlined in the manual.

47.Check that all pre-ignition checks are completed, including verifying fuel and air supply and inspecting ignition components.

- Defective or Outdated Control System

48.Reason: A malfunction in the burner control system can prevent proper ignition, especially in low nitrogen burners with more advanced control mechanisms.

49.Treatment Measures:

50.Inspect the burner control system for faults or failure in sensors, actuators, or controllers.

51.Recalibrate or replace the control system components if needed.

52.Ensure the software (if applicable) is up-to-date and functioning properly.

General Maintenance Tips:

53.Regular Inspections: Regularly inspect key components like the ignition transformer, flame sensor, and burner nozzle.

54.Cleanliness: Maintain a clean burner system to prevent soot or debris buildup, which could hinder performance.

55.Professional Service: Engage professionals for annual or bi-annual servicing to ensure everything is functioning optimally and to catch any issues before they cause major problems.

By identifying and addressing these potential issues, you can significantly reduce the chances of ignition failure in a low nitrogen burner. Regular maintenance and prompt troubleshooting are essential to ensure smooth and efficient operation.